44 inches (1.2 metres) in length may, to some modellers, seem to be pushing the size of

your latest creation, but that 44 inches is just what David Sisson had in mind when

constructing an exact replica of Moonbase Alpha's "workhorse" spacecraft. After all, this was

the precise size of the largest of four scales of the EAGLE, 44", 22", 11" and 5.5", that the

FX crew used for the model filming and, being an avid fan of the design since first seeing

"Space 1999" in the late 70s, David, who lives in Nottingham in England, just couldn't resist

the temptation! (Article and photos by David Sisson.)

I began building model kits when I was nine years of age, most of them

being WWII aircraft. After several years my bedroom was filled with every

type of Spitfire that was available, as well as some that I had modified from

others. The Spitfire was my first love - she has fantastic lines and sounds

wonderful and is the best plane at any airshow. Then, in 1975, I first saw

"Space 1999" and I'm afraid that all the aircraft models ended up in the

attic so that my bedroom could fill up with EAGLES. Unfortunately, the big

difference between the Spitfire and the EAGLE is that you can buy many

good plastic kits of the Spit', but Airfix rather let us down with the EAGLE

model - what a crap kit! What a rip-off!

I spent a lot of time on the EAGLE kits, adding extra detailing, cutting

out the girderwork and each one I built managed to be a little less awful

than the previous one! Then, in 1980, I saw the original 44 inch long studio

version for the first time. After drooling over it for about an hour, I returned

home and threw all my EAGLE kits into the attic. I decided that, one day, I

would build an EAGLE just like the one I had seen. But I realised that, at

that time, I wasn't anywhere good enough to start, so I decided to

practise by building a few Thunderbird models. Ten years later, I thought I

was good enough to begin - so I did.

The first thing I needed was a decent blueprint and there is one in the

old Gerry Anderson magazine, S.I.G. #10. This blueprint, drawn by Phil

Rae, is very good because firstly, Phil can draw and secondly, the original

model is part of his mammoth collection. However, I didn't want to build a

model using this drawing because errors were bound to crop up if I scaled

it up to the required large size. With Phil's kind permission, I was able to

take a series of measurements from the model to draw up my plans,

although after a short while, I realised that as the EAGLE is a modular

design with a lot of repeated patterns, it was only necessary to blueprint a

couple of small areas and the rest could just be built straight from my

measurements.

I could have started on virtually any part of the model but building the

basic frame seemed to be the most obvious thing to do. So the first job

was trying to decide how much brass pipe I needed to buy. Most of the

pipe on the original model is 1/4 inch diameter, with a fair amount of 3/16"

and a little bit of 5/16". My average estimate came out at 90 feet of pipe

which is rather a lot to get hold of. Years earlier I had built a smaller

EAGLE and all the brass was bought from model shops where a few tiny

lengths can cost a fortune. So this time I looked in the Yellow Pages under

Non-Ferrous Metal Stockists and eventually located a supplier on a local |

industrial estate. It was quite a pleasant change to buy the stuff more

cheaply and then have someone thrusting spare six foot lengths of brass at

me with the words, "You might as well take it mate," because they couldn't

be bothered to price it up!

Safely back home with my hundred and something feet of brass, I sat at

my workbench and began - that is I began to wonder how I was going to fix

it all together. The first time I had built an EAGLE I did it the hard way -

cutting all the pipes to the correct lengths and then trying to solder it all

together - wrong! The smart and easy way is to cut the horizontal lengths

longer than required so the extra bits can be used to help support the

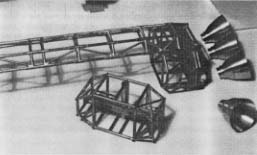

assembly. The framework basically breaks down into three sections - the

main top frame and the two mid-sections that the rest of the model hangs

onto Tackling one of these mid-sections first, I took a piece of 2mm

plasticard and drew out the cross-sectional shape required, then carefully

drilled eight 1/4 inch holes. When I was satisfied with the positioning of

these holes, a duplicate was made and the two pieces were carefully

positioned about seven inches apart. Eight lengths of 1/4 inch brass were

then pushed throught the holes, forming the exact shape needed. Now, I

just had to cut all the connecting pieces to length and solder it all together.

It sounds simple, but it was a lot of hard work and there was a problem

straight away.

ABOVE: The basic fame of the EAGLE being soldered together. |

|